Sandip Shah, argues “Low and Medium fidelity prototypes do co-exist, but the increasing popularity of High fidelity prototypes, due to exceptional end results and outputs, is really promising”

December 17, 1903 was a normal day for rest of the people, as they were not aware that Wright Brothers were about to change their world. Undeterred by numerous failures where they crashed, and broke several parts of their flying prototype; they once again lugged their 600 pound machine over a quarter mile uphill to lace it on a 60- foot monorail. But this time their flying machine made its way down the monorail and picked up speed. As the machine left the ground, a camera shutter opened, capturing one the most inspiring moments in human history. Twelve seconds and 120 feet later, Wright Brothers established that what was previously impossible was now a reality.

Innovation and failure go hand in hand – If you are not failing, you are not innovating. Your fear of failure will suffocate your creativity and progress. You can do a great favor to your product or service; embrace failure and blueprint a plan that affords you the opportunity to do it early and very often. Rapid Prototyping helps you do exactly that.

“Get your point across – effectively and efficiently”

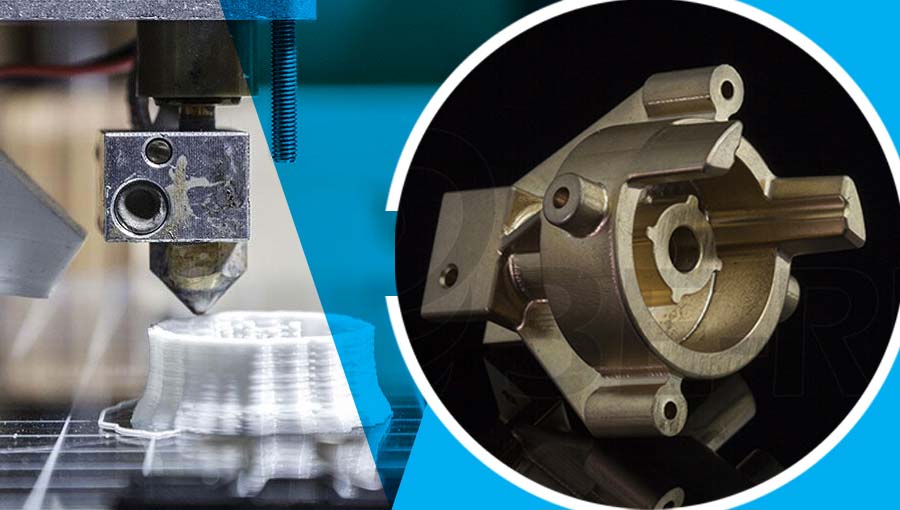

Rapid Prototyping builds the main feature path of an interface with modern 3D printing and manufacturing methods direct from the parts and assemblies. One of the biggest benefits of prototyping your product design is that they conveniently put your idea in front of potential end-users and key client stakeholders. Getting the conceptual idea out of the designer’s brains and into a demonstrable format is an effective process for eliminating initial shortcomings and misplaced design assumptions.

“There are a ton of companies, from one- and two-person organizations to sub-100-person organizations, that actually make themselves competitive with the 10,000-pound gorilla in their particular marketplace because of the advantages they get with 3-D printing” Bruce Bradshaw, marketing director at Stratasys.

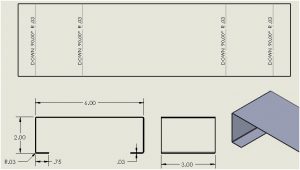

Additionally, mechanical design engineers also assist you in opting for the right kind of technology and material, ensuring comprehensive inclusion of required features in the prototype being developed. A one stop 3d prototyping service provider can also assist you with CNC machining, metal 3d printing, vacuum casting and SLA & SLS. Advanced outsourcing benefits and convenience makes it appropriate to hire a dedicated rapid prototyping team for additive manufacturing projects, who are a guarantee that the design data is converted to printer friendly CAD formats with resized holes, optimized tolerances, watertight geometry and balanced part density and strength. They make it happen with help of 3D CAD solid modeling tools such as SolidWorks, Inventor, Creo and SolidEdge to build printer-friendly CAD models for prototype requirements.

Image exports and slide decks, in this world of interface design, are very irrelevant way of conveying design ideas. Even for systems with modest complexity, static visual renderings represent a predetermined small sampling of the entire solution. Include the quick prototyping in the design process and it will not only help you communicate your ideas but will also empower you to harness one of the virtues of creating something truly innovative.

Rapid Prototyping is a cyclical and iterative process in tandem with design explorations. Testing and refining of the product or service early and often which includes ideate, prototype, test, analyze, refine and repeat; are facilitated by the basic cycle. Basic understanding while adapting a design process to an iterative one is that failure must be expected and embraced with open arms. It is so because this process will also create opportunities to remedy those failures ASAP and efficiently.

“Most of the revenue lies on the industrial side of things. I think that the way that this market is going to grow is that we’re going to start taking more jobs from the subtractive manufacturing world.” Andrew McCalip, cofounder and CTO of Cosine.

“Good news for product manufacturers”

With help of specialized development knowledge of the mechanical design support service provider, prototyping can be done at any phase across the design process. Development knowledge of the design service provider, said that, they should be capable to answer and decide, what and how to mock up, what the product’s or service’s needs are, and the technical resources available. Upon attaining these, effective results can be attained from various level of fidelity.

“Low and Medium fidelity prototypes do co-exist, but the increasing popularity of High fidelity prototypes, due to exceptional end results and outputs, is really promising” Sandip Shah, Sr. Manager, Industrial Design Division at Hi-Tech iSolutions LLP.

These high fidelity prototypes definitely portray the end vision for the interface and often include realistic content, refined interactions, transitions and animated effects. Some may find the process to be a bit time consuming, however; it goes a long way in usability testing and design presentations, as compared to other two.

Because these high fidelity prototypes show design directions as well as interactive interface experiences, they have an important role in defining a vision for manufacturers of their products or services that executives can clearly visualize.

Conclusion:

With rapid prototyping (RP) establishing itself as a major contributor to all 3D printing applications, we at Hi-Tech iSolutions LLP thought it would be great to spell out why RP has gained so much traction among product manufacturers. Product manufacturers instead of being skeptical about RP, should embrace it with open arms. The more frequently they fail, the more innovative ideas they would come up with.

In an effort to bridge the gap between virtual design and actual manufacturing; engineers and industrial designers should be intelligent and experienced enough to resist their urge to pack in as many features as possible. A prototype would enable you to see how it holds over time and in different environments. It emulates the structural, aesthetical and textural attributes of the final product, which becomes a powerful selling tool which images or animated demos can’t catch up to.

Additive manufacturing helps industrial designers and engineers to enjoy the freedom to make multiple design changes to a product before it is realized in tangible form. Today, the question of manufacturability of products is a ghost from past.

Printing a prototype with help of additive manufacturing certainly costs a manufacturer significantly less if compared to tool based manufacturing methods. These savings either can be passed on to the customers in form of lower product prices, or may be diverted towards product development, or can be added up as company profit.